Why Chefs Rely on Delfield's Blast Chillers

Oct 31st 2019

Blast chilling and shock freezing is a popular method many restaurants, caterers, bakeries and ice cream shops have come to rely on to improve the quality and organization of their workflow. If preserving the tastiest food stock safely and most efficiently is a top priority of your commercial food business, consider a Delfield eVent blast chiller for your equipment line-up. The e-Vents are available in a variety of sizes and capacities, even an undercounter size. These are hard-wired units that offer plenty of functions including four different modes of blast chilling, offering various degrees of chilling ranging from LIGHT for delicate products up to FAST for massive loads or dense items. By using a blast chill or shock freeze method, the bacterial growth process that begins immediately after cooking ends will be prohibited.

Product Safety will Increase

In short, this means blast chilling will prohibit the bacterial growth that can occur when a product temp ranges+149 °F and +50°F. The blast chiller is designed to get product quickly and safely +38°F at its core. As a result, making it healthier and safer. Shock freezing is the most reliable process to stop product cells macro-crystallization. That shock will stop the damage of the food cells.

The eVent can be used to blast chill or shock freeze all kinds of food product, as well as thaw and defrost or dry. It even offers an ice cream cycle. All the functions are easy to set via the digital operating panel. There is the ability to store and use up to 99 programs, tailoring this piece of equipment for your business's needs. The control display default is in English, you can also choose Italian, German, French, Spanish and Polish languages.

Food Quality will be Saved

The Delfield eVent will preserve your foods best qualities such as flavor, and shelf-life. Resulting in a reduction of waste of food stock. A blast chiller will also give your foods less dehydration. Delfield is happy to boast, "These are the main reasons why blast chillers are essential elements for food safety, in accordance with HACCP rules."

Blast Chillers Will Increase Profit Margins

Using a blast chiller will reduce waste, because food stays fresher longer, you can take advantage of seasonal ingredients when they are at their peak for both flavor and cost. Food will not evaporate as they often do after cooking. That evaporation means less weight loss of your product. You also can save time as well by prepping a larger amount of food batches all at once and using them as needed.

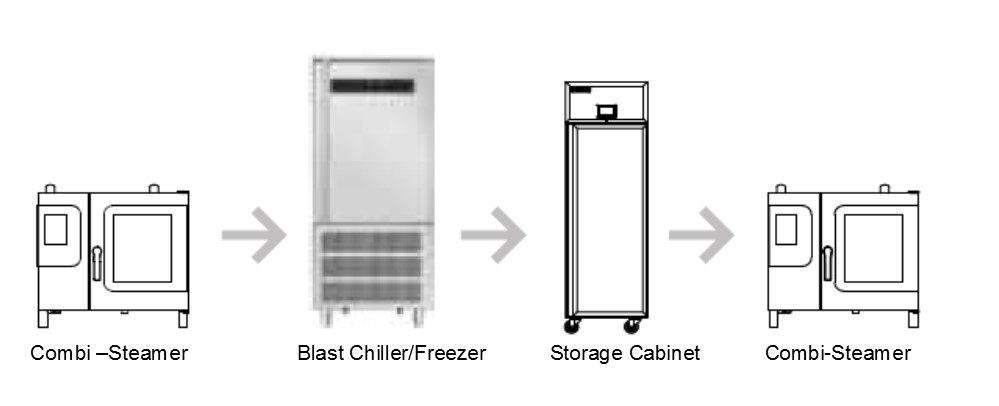

An example of Blast Chilling use in Foodservice:

Many restaurants find using this system of food prep, cooking and storing not only gains efficiency, but also increases the number of menu items they are able to offer.

Give Globe a call today for a quote on a blast chiller for your equipment line up. We can be reached at 800-972-4972.

About Delfield:

Since 1969, the Delfield Company manufactures and markets a complete line of foodservice equipment for restaurants, hotels and institutions. Specializing in custom and reach in refrigeration, such as salad and sandwich prep tables, pizza prep tables, undercounter and worktop refrigeration, refrigerated equipment stands, reach-in and roll-in refrigeration, blast chillers and blast freezers, mobile serving lines, milk coolers, plate and tray dispensers, display cases, modular chef counters and serving lines and custom production centers. In October 2008, Delfield became part of Welbilt. The Welbilt Company currently remains a leader in the foodservice equipment industry. Today, Delfield is one of the largest custom stainless steel refrigeration equipment manufacturers in the world.