All About Under Counter Dish Machines

Apr 6th 2012

A commercial under counter dishwasher can really improve the efficiency of small kitchens. Depending on the manufacturer and style of the dishwasher, you can wash up to 45 racks per hour! This style of dishwasher is ideal for coffee shops, church kitchens, corporate kitchens, smaller restaurants with isolated busy times.

|

Without Soap Pumps |

With Soap Pumps |

|

| Price | Less expensive | More Expensive |

| Soap | Provided by pump rental agency - You are tied to their soap prices | Purchased anywhere and soap prices can be shopped around |

| Total Cost of Ownership | Use the dish machine for 5 or less years, this is more cost effective | Use the dish machine for more than 5 years, overall cost of ownership will be less |

After the dishwashers clean the items inside, they need to sanitize that product. This can be done in two ways - with heat or with chemicals. That leads us to the other big difference in under counter dish machines.

Hot water sanitizing or chemical sanitizing?

- With hot water sanitizing, the dish machine would have a booster heater to take your incoming water, and bring it up to a temperature of 180 degrees. At that temperature, any bacteria on the dishes will be killed.

- With a chemical sanitizing dishwasher, you use standard water temperature and inject a sodium hypochlorite solution (liquid bleach) into the machine to sanitize.

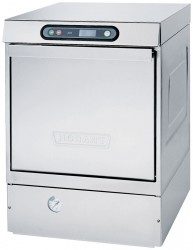

Pictured at right: Hobart LXiH Dishwasher has digital controls and uses only .74 gal of water per rack washed.

| Hot Water Sanitizing | Chemical Sanitizing | |

| Price | More expensive | Less Expensive |

| Chemicals Needed | Only soap for the wash cycle (rinse aid can also be used but is not required) | Soap and a chemical sanitizer |

| Water Consumption | Less water use | More water use |

| Booster Required | Yes / Internal with the machine or external | No booster required |

| Rinse Aid Recommended for Spotting | No - Water evaporates at 180 degrees preventing spotting | Yes |

| Electrical Requirements | 208 / 240v | 115v |

Other things to consider when purchasing a dishwasher :

Fill and Dump vs. Recycled Water - The most cost effective way to produce a dishwasher is a fill and dump style. This is when each wash and rinse cycle use fresh water. The initial cost of the machine is a lot less, but your electrical and water costs go up. The other option is where you recycle the water from the clean rinse cycle to be used in the next wash cycle. What this does is reduces the amount of water needed for each wash as well as reducing the electrical needs since the water going into the wash cycle is already hot and does not need to be heated.

Finished or Unfinished Exterior - Depending on the location of where the dish machine is going, it may not be necessary to have finished top and side panels. For example, if the dish machine is being built into a cabinet, will be against a wall, or under a dish table, top, left, and right side panels may not be needed which can save money. Otherwise, the exterior of the dish machine will be generally finished in stainless.

Digital vs Analog Controls - Another feature to look at in a dishwasher would be if there are digital or analog controls. Digital controls can tell you the precise temperature of the water, time remaining in the cycle, and also give you diagnostic codes if there are issues with the machine. A basic machine will have a temperature and pressure gauge along with a start button.